What is a Fish Meal Plant?

A fish meal plant is a specialized facility where fish by-products and whole fish are processed into fish meal and fish oil. This process transforms raw fish materials into a high-protein, nutrient-dense product widely used in animal feeds, aquaculture, and fertilizers. Understanding what a fish meal plant entails can help industry professionals and interested parties appreciate the intricacies and importance of this process.

What Does a Fish Meal Plant Do?

A vismeel plant undertakes the task of converting fish waste and by-products into valuable commodities. The primary products are fish meal, which is used in animal feed, and fish oil, which has various applications in food and industrial products. This transformation involves several key stages, including kook, druk, droogmaak, and milling.

Key Features of a Fish Meal Plant

1. Efficient Processing: Fish meal plants are designed to handle large volumes of raw fish materials efficiently. The plants incorporate advanced machinery that ensures the processing is conducted swiftly, minimizing waste and maximizing output.

2. High-Quality Products: One of the primary goals of a fish meal plant is to produce high-quality fish meal and fish oil. This involves stringent quality control measures at every stage of production to ensure that the end products meet the required standards.

3. Environmental Considerations: Modern fish meal plants are built with a focus on environmental sustainability. They incorporate systems to manage waste and emissions, ensuring that the processing of fish by-products does not adversely impact the environment.

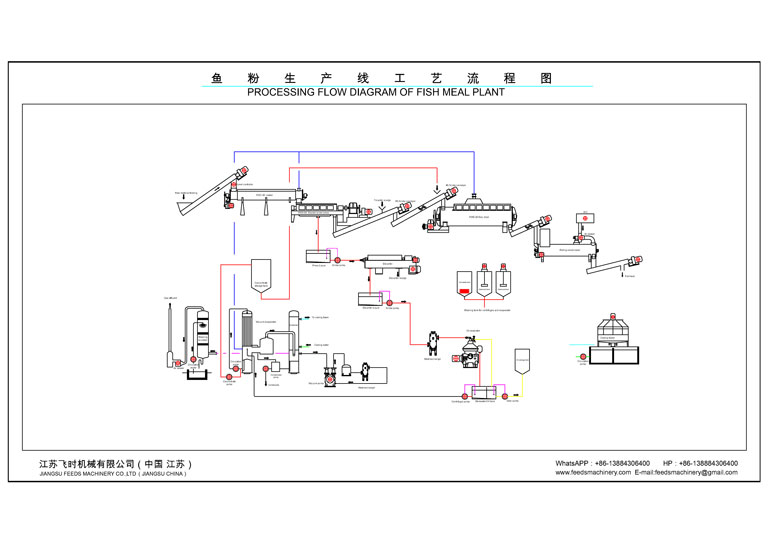

How Does a Fish Meal Plant Work?

1. Raw Material Reception: The process begins with the reception of raw materials, which include fish by-products and whole fish that are not suitable for human consumption. These materials are sorted and stored in appropriate conditions to prevent spoilage.

2. Cooking: The raw materials are then cooked to coagulate the proteins and separate the water and oil from the solid fish material. This step is crucial as it prepares the materials for subsequent processing stages.

3. Pressing: After cooking, the mixture is pressed to extract fish oil and water from the solid fish material. The solids, known as press cake, are then moved to the drying stage.

4. Drying: The press cake is dried to reduce the moisture content to a suitable level. This ensures that the fish meal has a longer shelf life and is safe for use in animal feeds.

5. Milling and Packaging: Finally, the dried fish meal is milled to the desired consistency and packaged for distribution. The fish oil is also processed and stored in containers for shipment.

Applications of Fish Meal and Fish Oil

Fish meal and fish oil produced by fish meal plants have a wide range of applications:

- Animal Feed: Fish meal is a critical ingredient in the diets of livestock, poultry, and aquaculture species due to its high protein content and digestibility.

- Fertilizers: Fish meal is also used in organic farming as a natural fertilizer, providing essential nutrients to crops.

- Food and Industrial Uses: Fish oil is used in various food products, dietary supplements, and industrial applications such as biodiesel production.

Choosing the Right Fish Meal Plant Machinery

When setting up a fish meal plant, selecting the right machine is crucial. Factors to consider include the capacity of the plant, the types of fish materials being processed, and the desired end products. Investing in high-quality machinery from reputable manufacturers ensures efficient processing, high-quality outputs, and compliance with environmental standards.

Conclusion

A fish meal plant plays a vital role in transforming fish by-products into valuable products such as fish meal and fish oil. By understanding the process and the features of a fish meal plant, stakeholders can appreciate the importance of this industry in supporting animal feed production, agricultural practices, and various industrial applications. When considering the establishment or upgrade of a fish meal plant, it is essential to focus on efficiency, product quality, and environmental sustainability to ensure success.