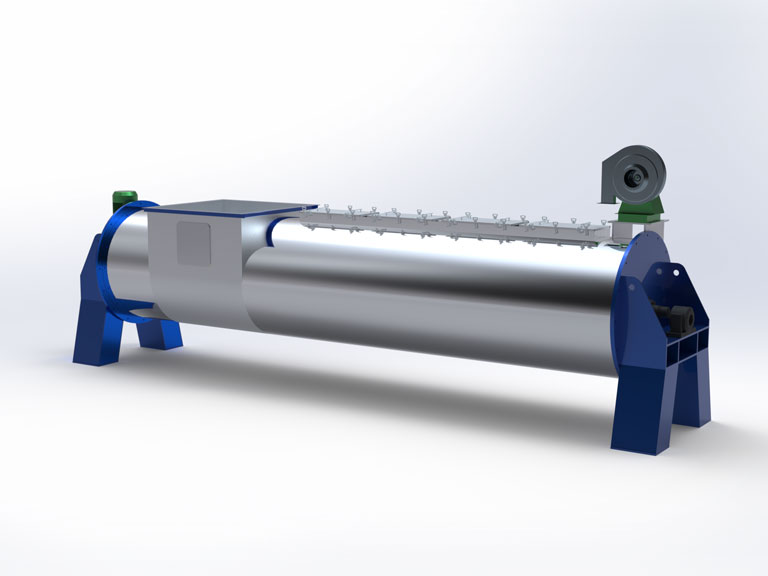

What is the meal cooler?

A Meal Cooler is a device used to cool the heat generated during powder processing. It employs advanced cooling technologies to lower temperatures using air or water, ensuring that products maintain optimal temperatures throughout processing.

The Meal Cooler is primarily used during the cooling stage of powder processing. It effectively lowers product temperatures to prevent quality loss due to overheating, ensuring the stability and quality of the final product.

What can fish meal dryer do?

The meal cooler is suitable for various powder processing applications including fish meal processing, meat meal processing, shrimp meal processing, and more, the Meal Cooler is an essential equipment for ensuring smooth processing and stable product quality.

Related Posts

Related Products

We also offer customized fish meal processing solutions, including production lines, drying equipment, and oil separation.