What is a fish meal dryer?

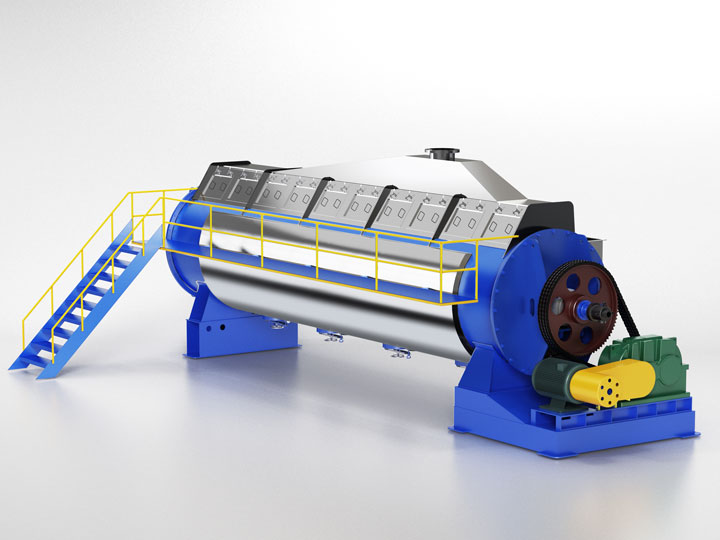

The FM series fish meal dryer stands out from traditional fish meal disc dryers with its unique spindle design.

Specifically, the main shaft is designed to prevent direct contact between the material and welding seams, thereby reducing wear and corrosion and prolonging the dryer’s service life.

Additionally, we offer customized options for the fish meal dryer in various sizes and specifications based on the desired output and transportation conditions.

Moreover, depending on the material properties, the fish meal dryer can be constructed from carbon steel Q345, stainless steel 304, 316L, or bi-directional stainless steel.

Seamless steel tube spindle

Adopt seamless steel tube to avoid the risk of spindle breakage

Hidden Seam Design

Reduce the wear of discs and materials and prolong the service life

Stainless Steel Bezel

Prevent the material from slipping in the blade and improve the drying efficiency for fish meal

What can fish meal dryer do?

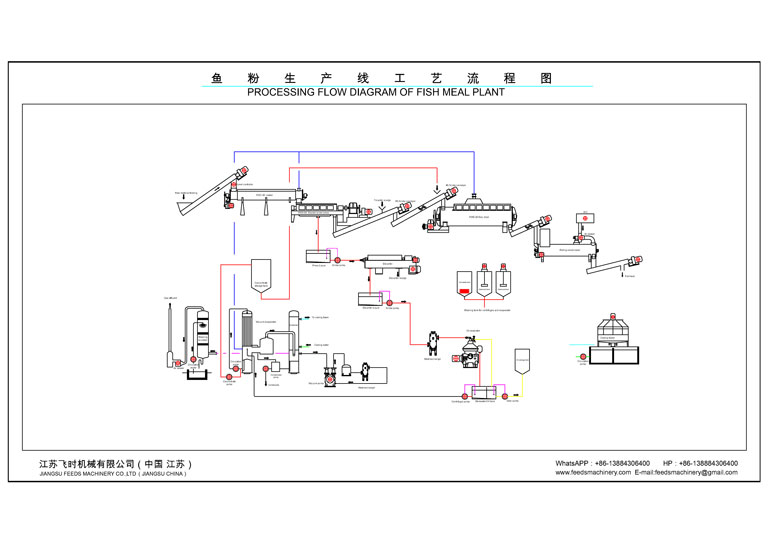

The process of pressing, cooking, and drying is utilized by the fish meal dryer to produce a high-quality fish meal from cooked fish or fish waste.

Also, the dryer’s primary objective is to eliminate the excess water and moisture from the fish meal, ensuring that it retains its quality and remains preserved.

Additionally, the dryer can also be used to dry other materials with similar properties, such as bone meal, meat and bone meal, and feather meal, expanding its range of applications.

How does the fishmeal dryer work?

Furthermore, the fish meal dryer features a unique design that uses a combination of pressing, cooking, and drying processes to produce high-quality fish meal.

Additionally, The material is continuously transferred from the feed end to the discharge end using the pusher system located on the outer edge of the blade.

In addition, the fish meal dryer utilizes high-quality seamless steel pipes to install heating blades, and a stainless steel scraper is inserted between the heating blades to ensure thorough evaporation of water by stirring the material.

Moreover, The machine collects and continuously discharges water vapor via an induced draft fan.

Furthermore, The dryer uses a slow spindle speed of 10 to 12 rpm, and used a speed-adjustable screw conveyor to regulate the discharge rate.

Model

| Model | Disc Diameter | Size(mm) | Motor Power(Kw) | Heating Area(m2) | Capacity(Mt/24h) |

|---|---|---|---|---|---|

| FM-50 | 1200 | 7600X2000X2850 | 37 | 96 | 50 |

| FM-80 | 1450 | 8300X2500X3100 | 45 | 158 | 80 |

| FM-100 | 1450 | 10000X2500X3100 | 55 | 198 | 100 |

| FM-150 | 1700 | 11200X2500X3200 | 75 | 261 | 150 |

| FM-200 | 1950 | 11800x3000x3500 | 110 | 350 | 200 |

Related Posts

Related Products

We also offer customized fish meal processing solutions, including production lines, drying equipment, and oil separation.