What is a fish oil separator?

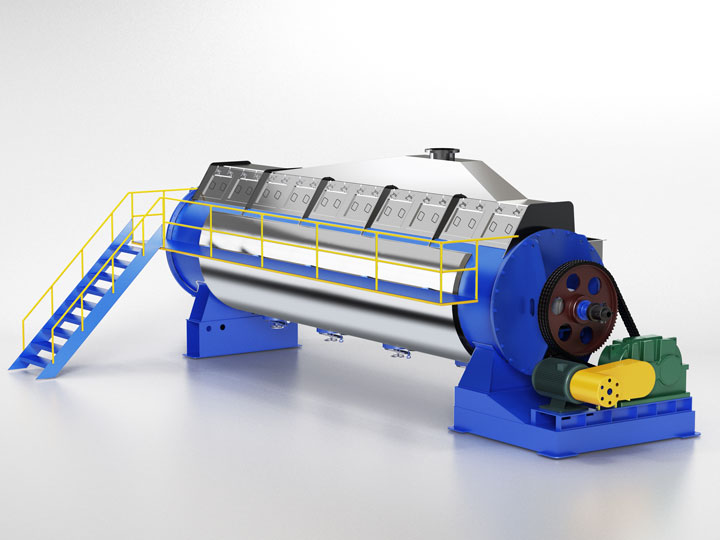

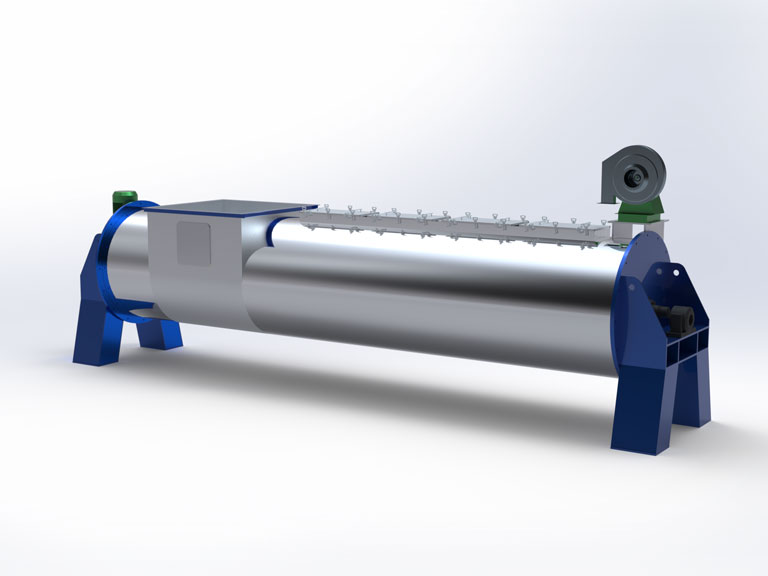

Our disc separator is specifically engineered to efficiently and dependably separate fish oil and water from various fish processing wastes. In addition, the separator utilizes the principle of high-speed centrifugal force to separate the fish oil from other substances, resulting in a high-quality product with a long shelf life.

What can fish oil separator do?

The fish oil disc separator is ideal for use in various fish processing industries, including fish meal processing, fish oil production, and fish farming. In addition, the separator can be used to extract fish oil from different types of fish waste, including fish heads, bones, and viscera.The separator is also suitable for the separation of other liquids with similar densities, such as milk and fruit juice.

How does the fish oil separator work?

The fish oil disc separator operates by utilizing the principle of high-speed centrifugal force to separate the fish oil from other substances. In addition, the separator is equipped with a series of stacked discs that rotate at high speed, creating a centrifugal force that separates the different substances based on their densities.

As the mixture of fish oil and water enters the separator, the heavier water particles are pushed to the outer edges of the rotating discs while the lighter fish oil particles move towards the center. The separated fish oil is collected in a separate chamber, while the water is discharged through a separate outlet.

The separator is designed with a self-cleaning mechanism that ensures continuous operation by removing any accumulated solids from the disc surfaces. The separated fish oil is of high quality and can be further processed into a variety of products including fish feed, nutritional supplements, and industrial lubricants.

Model

| Model | Capacity(L/h) | Size(mm) | Motor Power(Kw) | Weight(t) |

|---|---|---|---|---|

| FM-DS270 | 500-1200 | 900X1200X1100 | 4 | 0.42 |

| FM-DS360 | 1200-2500 | 1500X1150X1500 | 7.5 | 1.28 |

| FM-DS380 | 2500-5000 | 1555X1130X1629 | 11 | 1.5 |

| FM-DS470 | 5000-6000 | 1800X1200X1800 | 15 | 1.88 |

| FM-DS500 | 1950 | 1800X1250X1800 | 22 | 1.95 |

| FM-DS550 | 6000-15000 | 1850X1550X2050 | 22 | 2.2 |

| FM-DS700 | 15000-30000 | 2100X1650X2300 | 30 | 3.3 |

| In addition, the material selection according to different raw materials: carbon steel, 304, 316L, double-sided stainless steel, etc. | ||||

Related Posts

Related Products

We also offer customized fish meal processing solutions, including production lines, drying equipment, and oil separation.