The drying process is a critical stage in fishmeal processing, yet traditional drying equipment often suffers from high energy consumption. This not only increases production costs but also places a burden on the environment. This article analyzes the energy consumption issues in the drying process of fishmeal processing and introduces our company’s new, energy-efficient disc dryer.

Energy Consumption Issues in the Drying Process

In fishmeal processing, the drying stage is a significant energy consumer due to several key reasons. Traditional drying equipment typically has low thermal efficiency, meaning a large portion of the heat generated is lost during the process. Additionally, many systems lack effective heat recovery mechanisms, leading to higher energy usage. The aging of equipment and outdated technologies further contribute to excessive energy consumption.

Solutions to Reduce Energy Consumption

To address these issues, several strategies can be implemented to reduce energy consumption in the drying process:

Improve Thermal Efficiency: Utilizing advanced heat transfer technologies and high-efficiency insulation materials can minimize heat loss during the drying process. Optimizing the design of the drying chamber to ensure more uniform heat distribution can also enhance drying efficiency.

Enhance Heat Recovery Systems: Installing efficient heat recovery devices can capture waste heat from exhaust gases and reuse it to preheat raw materials or other process steps. This significantly reduces the demand for new heat energy, thus lowering overall energy consumption.

Upgrade Equipment Technologies: Introducing advanced drying technologies such as heat pump drying or microwave drying can not only reduce energy consumption but also improve drying speed and product quality. Regular maintenance and upgrades of equipment ensure they operate at peak performance levels.

Advantages of FEEDSMACHINERY’s Disc Dryer

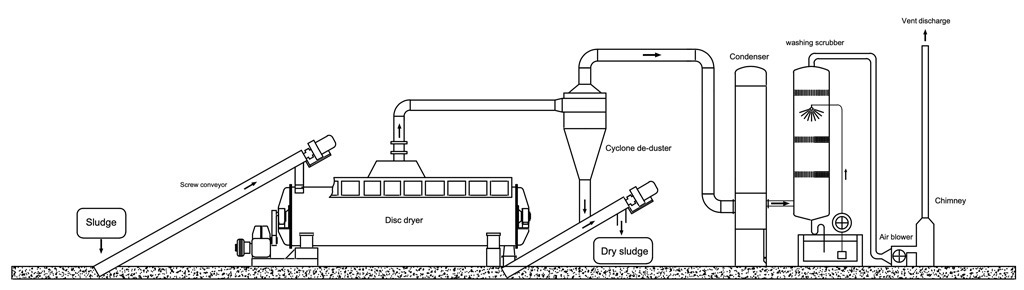

To solve the energy consumption issues in the drying process of fishmeal processing, our company has developed a new disc dryer that offers significant advantages in terms of energy efficiency and performance. This equipment is the ideal choice for fishmeal processing enterprises.

High Energy Efficiency: Our disc dryer employs the latest heat transfer technologies, achieving high thermal efficiency and fast drying speeds. It is also equipped with an advanced heat recovery system that recycles waste heat from exhaust gases for preheating purposes, significantly reducing energy consumption. Compared to traditional drying equipment, our disc dryer can reduce energy consumption by approximately 30%.

Environmentally Friendly with Low Emissions: Designed with environmental protection in mind, our disc dryer has low exhaust gas emissions that meet international environmental standards. The integrated exhaust gas purification system effectively removes harmful substances, reducing environmental pollution.

Automated Control: The disc dryer features an advanced automated control system that allows for real-time monitoring and adjustment of the drying process, ensuring optimal drying results with minimal energy consumption. The system is user-friendly and requires minimal maintenance, reducing labor costs.

Durability and Reliability: Constructed with high-quality materials and advanced manufacturing processes, our disc dryer is exceptionally durable and reliable. It operates stably with low failure rates and minimal maintenance costs, ensuring a long service life.

By introducing our advanced disc dryer, fishmeal processing enterprises can significantly reduce energy consumption in the drying process, lower production costs, and enhance product quality and market competitiveness. Our equipment has been widely adopted and highly praised by numerous customers, making it a crucial asset for the green development of the fishmeal processing industry.