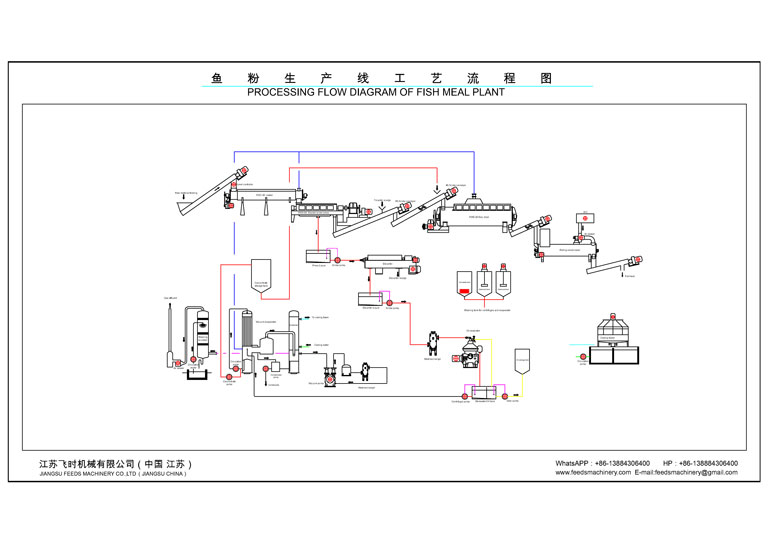

Fish meal production is an intricate process that involves several critical stages to ensure the quality and efficiency of the final product. Understanding these steps provides insight into how fish by-products are transformed into high-quality fish meal for various applications, especially in animal feed. At our company, we specialize in providing top-notch fish meal production equipment and customized plant solutions that cater to your specific needs. Here’s a detailed guide to the fish meal production process step by step, and how our products offer unmatched advantages.

1. Raw Material Selection and Preparation

The first step in fish meal production is selecting the raw materials, which generally include whole fish, fish by-products, and other seafood waste. The raw materials are typically gathered from fishing industries and other seafood processing plants. At this stage, it’s crucial to handle the raw materials efficiently to prevent spoilage.

Our piante di farina di pesce come equipped with advanced raw material handling systems that maintain the freshness and quality of the input, allowing for smooth processing. We offer fully integrated fish meal production solutions that streamline the preparation process.

2. Cooking

The cooking process is critical as it involves heating the raw materials to coagulate the proteins and separate the water and fat. Our fish meal cooker machines are designed to heat raw fish and fish waste uniformly, ensuring the highest yield of fish meal. This process effectively sterilizes the fish, making it safe for further processing.

3. Pressing

After cooking, the fish material is sent through the pressing phase, where water and oil are extracted from the fish mass. This step reduces the moisture content, further separating solid protein matter from the liquid phase. Our fish meal press machines are known for their efficiency, yielding higher-quality fish meal while minimizing waste.

4. Drying

The pressed fish cake is then dried to reduce the moisture content to the desired level, usually around 10%. This step ensures the long shelf life of the fish meal. We offer a range of fish meal dryers, including steam dryers and hot air dryers, to suit different processing requirements. Our equipment optimizes energy consumption, making your fish meal production more cost-effective.

5. Grinding and Sieving

Once the material is dry, it is ground into a fine powder. This process ensures that the fish meal meets the required particle size for animal feed. Our fish meal grinding machines ensure a consistent, uniform product that meets market standards.

6. Packaging and Storage

The final step in the fish meal production process is packaging and storing the fish meal for distribution. Proper packaging is essential to prevent moisture reabsorption and maintain the quality of the fish meal over time. Our packaging systems are designed to protect your product and simplify transportation.

Why Choose Us for Your Fish Meal Production Plant?

At our company, we pride ourselves on providing high-performance fish meal production equipment that is customized to suit the unique needs of our clients. Our experience in the industry has made us a trusted partner for fish meal plant solutions worldwide. Here are some key advantages of choosing us:

- Customized Solutions: We design and manufacture fish meal plants according to your production capacity and operational needs.

- High Efficiency: Our equipment maximizes yield and minimizes waste, ensuring cost-effective production.

- Energy-Saving Design: Our fish meal dryers and other machinery are optimized for energy efficiency, reducing operational costs.

- Comprehensive Support: We offer end-to-end support, from plant design and installation to after-sales service, ensuring smooth operations.

With our advanced fish meal processing equipment, you can be assured of efficient production, high-quality output, and seamless integration into your existing facility.

From raw material selection to final packaging, every step in the processo di produzione della farina di pesce is crucial for producing a high-quality product. Our company is dedicated to providing complete fish meal production plants that streamline each stage of the process. Whether you’re looking to upgrade your equipment or establish a new plant, our customized solutions are designed to meet your needs and ensure the success of your operation.

For more information on how we can help you with your fish meal production plant, contact us today!