What is a fish decanter centrifuge?

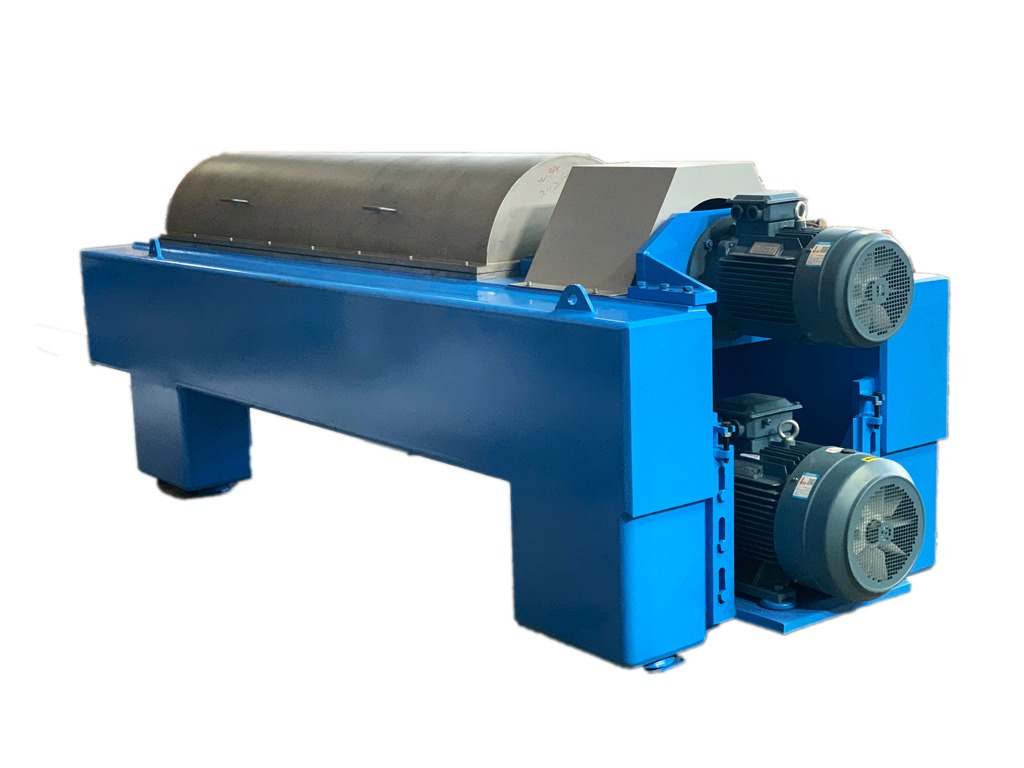

The decanter centrifuge is a machine specially designed for the fishmeal processing industry.

Its main function is to separate the water and oil in the fishmeal, so as to produce high-quality fishmeal.

The decanter centrifuge consists of various components such as a horizontal centrifuge, gear reducer, motor, hydraulic system, and control system.

What can fish decanter centrifuge do?

We widely use our horizontal screw centrifuge in the fish meal production industry to separate solid and liquid components in fish meal slurry.

It can also dewater other materials, such as wastewater sludge, food waste, and animal manure.

How does the fish decanter centrifuge work?

The horizontal screw centrifuge utilizes the principle of high-speed centrifugal force to separate solid and liquid components in the fish meal production process.

The fish meal slurry is fed into the machine through a feeding pipe and is rapidly accelerated by the screw conveyor, which rotates at high speed.

The centrifugal force separates the liquid component from the solid component, and it discharges through the liquid outlet. The screw conveyor pushes the solid component to the discharge port, and then it discharges through the slag outlet.

Related Posts

Related Products

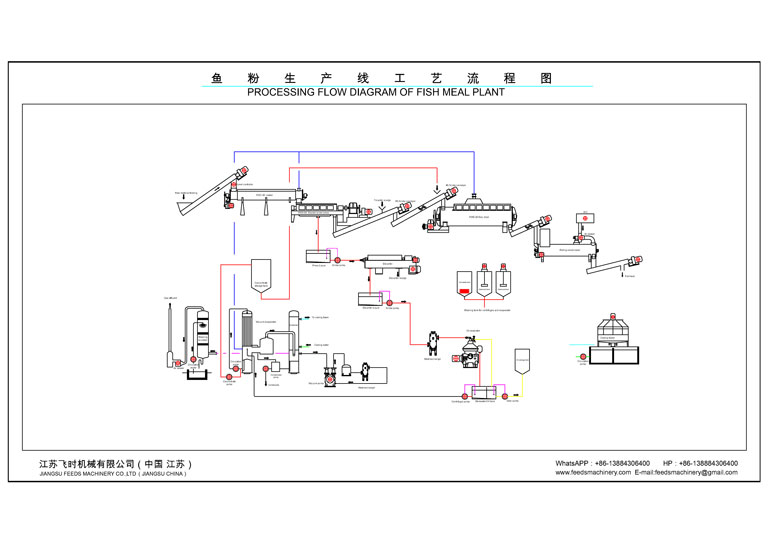

We also offer customized fish meal processing solutions, including production lines, drying equipment, and oil separation.