Fish meal production involves a series of complex processes that ensure high-quality protein and oil are extracted from raw fish materials. Understanding the processing flow diagram of a fish meal plant is crucial for ensuring efficiency and optimizing the production process. In this article, we will break down the key stages involved in fish meal production and introduce the unique advantages of our company’s fish meal processing solutions.

Key Stages in the Processing Flow of a Fish Meal Plant

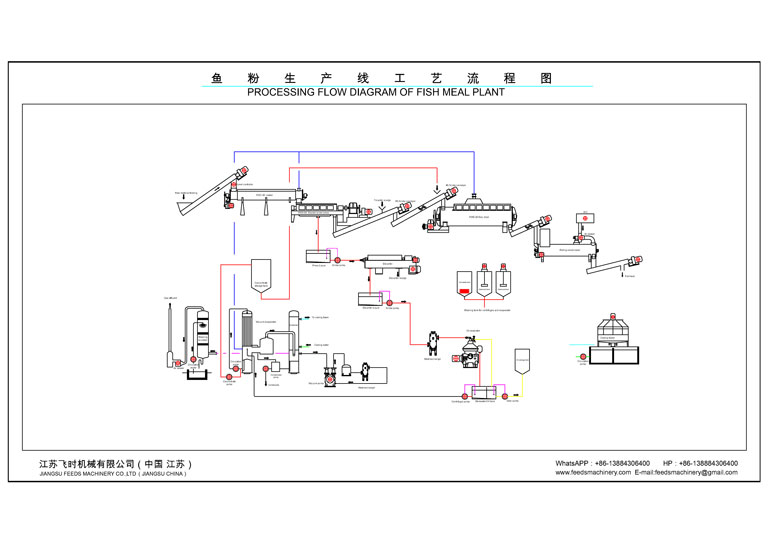

- Raw Material Reception and Storage The process begins with receiving and storing raw fish materials, which can include whole fish or fish trimmings. Proper handling at this stage ensures the preservation of raw material quality, preventing deterioration that may affect the final product.

- Cooking The raw materials are then transferred to the fish meal cooker, where they undergo heat treatment. Cooking is a vital process that helps in coagulating proteins and separating water and oil from the solid components. Our advanced cookers ensure uniform heating for optimal results.

- Pressing After cooking, the materials pass through the fish meal press machine (often a twin-screw press). This step helps to remove the liquid fraction (water and oil), leaving behind a solid cake. The extracted liquid is directed to the separation process, while the press cake is sent for further processing.

- Separation The liquid extracted during pressing is separated into fish oil and stickwater (which contains dissolved protein). The stickwater is concentrated using an evaporator, and the fish oil is refined for commercial use.

- Drying The press cake, still containing some moisture, is dried in a fish meal dryer or steam dryer. Drying reduces the moisture content of the fish meal to around 10%, ensuring it is stable and safe for storage.

- Grinding and Packaging Once dried, the fish meal is ground to the desired particle size and then packed for distribution. At this stage, the meal is tested for quality to ensure it meets industry standards.

Why Choose Our Fish Meal Processing Solutions?

At FEEDSMACHINERY, we offer a complete range of fish meal plant equipment designed to meet the specific needs of fish meal producers. Here’s why our solutions stand out in the market:

- Efficiency and Cost-Effectiveness: Our processing solutions are designed to minimize energy consumption while maximizing output. This results in significant cost savings and higher profitability for your plant.

- High-Quality Materials and Durability: We use corrosion-resistant materials and the latest engineering technologies to ensure our equipment can withstand the harsh conditions of fish meal production, offering a longer operational lifespan.

- Tailored to Your Needs: Every fish meal production facility is different, and we offer tailored solutions that meet the unique requirements of small, medium, and large-scale operations. Our equipment can be customized to your specific capacity needs and process flow requirements.

- Sustainable Production: Our equipment is designed with sustainability in mind. We prioritize reducing waste and emissions, helping fish meal plants comply with environmental regulations while improving overall process efficiency.

- Comprehensive After-Sales Support: From installation and commissioning to maintenance and troubleshooting, our team provides full after-sales support to ensure your plant runs smoothly at all times.