What is Falling Film Evaporator ?

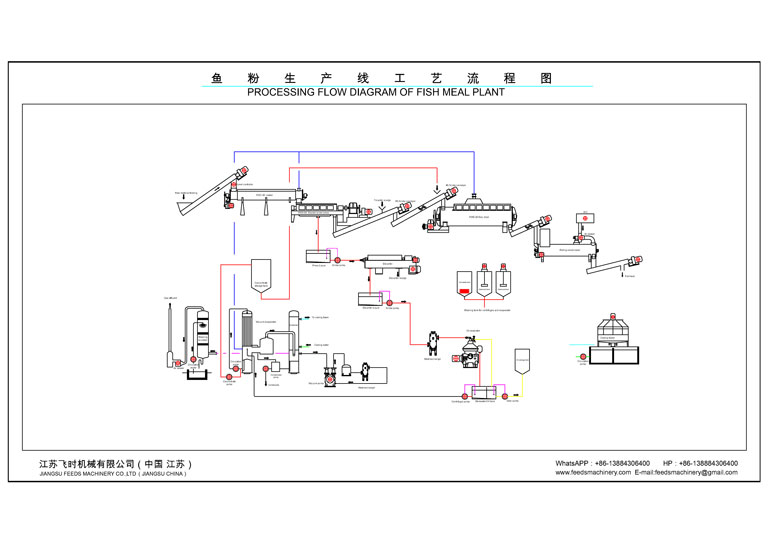

In the fish meal processing industry, efficiency and product quality are paramount. Falling Film Evaporators (FFEs) have emerged as game-changers, revolutionizing the way fish meal is processed and concentrated.

These innovative devices offer a multitude of benefits, including gentle product handling, high evaporation rates, reduced fouling, and suitability for low-pressure environments.

FFEs are heat exchangers that utilize a unique design to maximize evaporation efficiency and minimize product degradation.

In an FFE, the fish meal concentrate is fed into the top of the evaporator and flows down a series of tubes as a thin film. Hot water or steam circulates within the jacket surrounding the tubes, transferring heat to the falling film and causing the liquid portion to evaporate. The concentrated fish meal is then collected at the bottom of the evaporator.

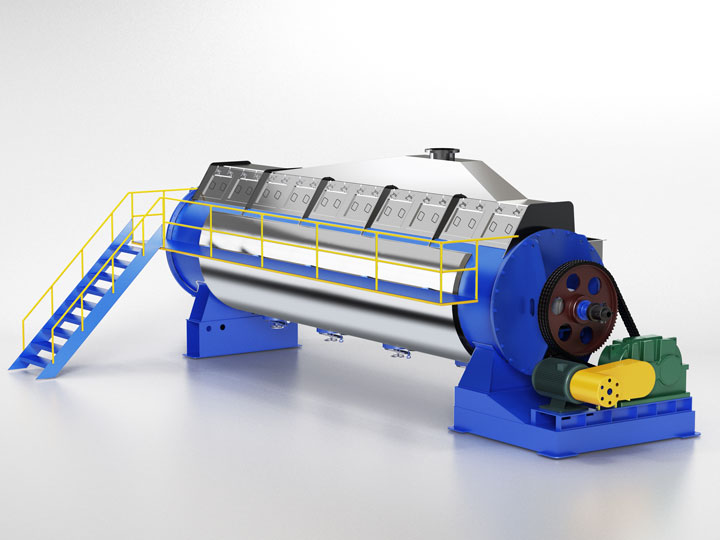

What can fish meal dryer do?

FFEs play a crucial role in fish meal processing, particularly in the concentration stage. They are specifically designed to handle the viscous and heat-sensitive nature of fish meal concentrate, ensuring optimal processing results.

Benefits of Using Falling Film Evaporators

Enhanced Product Quality: FFEs minimize heat exposure and product degradation, leading to higher quality fish meal with improved nutritional value and reduced off-flavors.

Increased Production Efficiency: The high evaporation rates and continuous operation of FFEs contribute to significant increases in fish meal production output.

Reduced Energy Consumption: The efficient heat transfer and low-fouling properties of FFEs lead to minimized energy consumption, lowering operating costs.

Simplified Maintenance: The reduced fouling and easy cleaning of FFEs minimize maintenance downtime and associated costs.

How does the fishmeal dryer work?

Falling Film Formation: The concentrate flows down the tubes as a thin film due to gravity and the slight pressure difference between the inside and outside of the tubes.

Heat Transfer and Evaporation: Hot water or steam circulates in the jacket surrounding the tubes, transferring heat to the falling film. This heat causes the liquid portion of the concentrate to evaporate, leaving behind a more concentrated fish meal mixture.

Concentrate Collection: The concentrated fish meal collects at the bottom of the evaporator, where it can be discharged for further processing or storage.

Model

| Model | Capacity(Mt/24h) | Evaporation(L/h) | Size(mm) | Motor Power(kw) | Outlet Concentration |

| FMCE-1500 | 50 | 1500 | 4000x2500x13000 | 35 | 28-35% |

| FMCE-2500 | 80 | 2500 | 4000x2500x13000 | 45 | |

| FMCE-3500 | 150 | 3000 | 5000x2500x13000 | 60 | |

| FMCE-5000 | 300 | 5000 | 6000x3000x13000 | 86 | |

| FMCE-12000 | 500 | 12000 | 8000x3500x13000 | 120 | |

| Material selection according to different raw materials: carbon steel, 304, 316L, double-sided stainless steel, etc. | |||||

Related Posts

Related Products

We also offer customized fish meal processing solutions, including production lines, drying equipment, and oil separation.