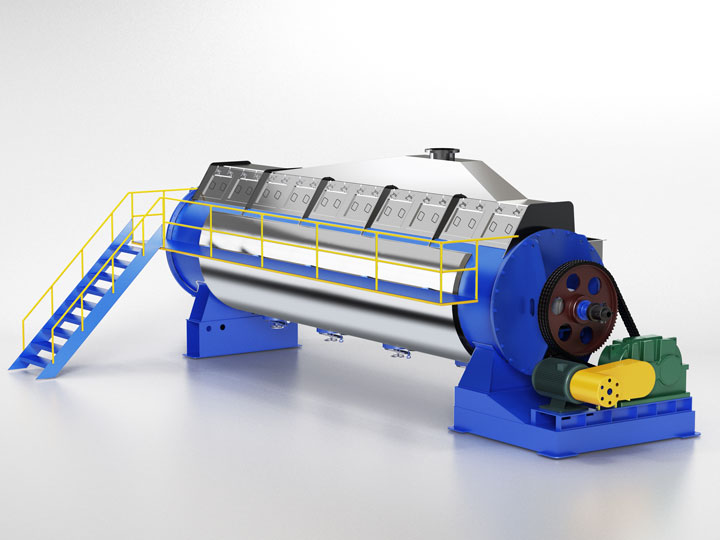

What is a disc dryer?

A Disc Dryer is an industrial drying machine commonly used in the processing of fishmeal, meat, and other by-products.

It utilizes rotating discs to distribute heat evenly across the material, ensuring efficient moisture removal.

Disc Dryers are known for their ability to handle high moisture content materials and produce a consistent, high-quality final product.

Seamless steel tube spindle

Adopt seamless steel tube to avoid the risk of spindle breakage

Hidden Seam Design

Reduce the wear of discs and materials and prolong the service life

Stainless Steel Bezel

Prevent the material from slipping in the blade and improve the drying efficiency for fish meal

What a disc dryer can do?

A Disc Dryer is designed to perform several key functions:

Torkning: Efficiently removes moisture from materials to produce a stable, dry product.

Heat Recovery: Utilizes advanced heat recovery systems to reuse waste heat, improving energy efficiency.

Consistent Output: Ensures uniform drying and consistent product quality.

Environmental Protection: Reduces emissions and environmental impact through efficient drying and advanced filtration systems.

How a disc dryer works?

A Disc Dryer operates by feeding the wet material into a chamber containing multiple rotating discs.

These discs are heated, typically by steam or thermal oil. As the discs rotate, they agitate the material, exposing it to the heat and facilitating moisture evaporation.

The dried material is then conveyed out of the chamber, while the evaporated moisture is collected and treated.

This process ensures efficient, uniform drying with minimal energy consumption.

Model

| Model | Disc Diameter | Size(mm) | Motor Power(Kw) | Heating Area(m2) | Capacity(Mt/24h) |

|---|---|---|---|---|---|

| FMD-50 | 1200 | 7600X2000X2850 | 37 | 96 | 50 |

| FMD-80 | 1450 | 8300X2500X3100 | 45 | 158 | 80 |

| FMD-100 | 1450 | 10000X2500X3100 | 55 | 198 | 100 |

| FMD-150 | 1700 | 11200X2500X3200 | 75 | 261 | 150 |

| FMD-200 | 1950 | 11800x3000x3500 | 110 | 350 | 200 |