Investing in โรงงานปลาป่น machinery is a significant decision for any business involved in fish meal production. The machinery cost can vary widely, depending on multiple factors, including equipment type, production capacity, and the level of automation. As one of the industry’s leading suppliers, our company offers a comprehensive range of high-quality fish meal plant equipment designed to meet diverse production needs. In this article, we will break down the factors affecting fish meal plant machinery cost and discuss why our company is the best choice for your fish meal production line.

Understanding the Cost of Fish Meal Plant Machinery

The cost of fish meal plant machinery depends on several key elements:

- Production Capacity

One of the biggest cost drivers in fish meal machinery is production capacity. Small and medium-sized plants require smaller machinery, which costs less. However, large-scale industrial fish meal plants require high-capacity machines, which are more expensive due to their ability to process larger volumes. - Type of Equipment

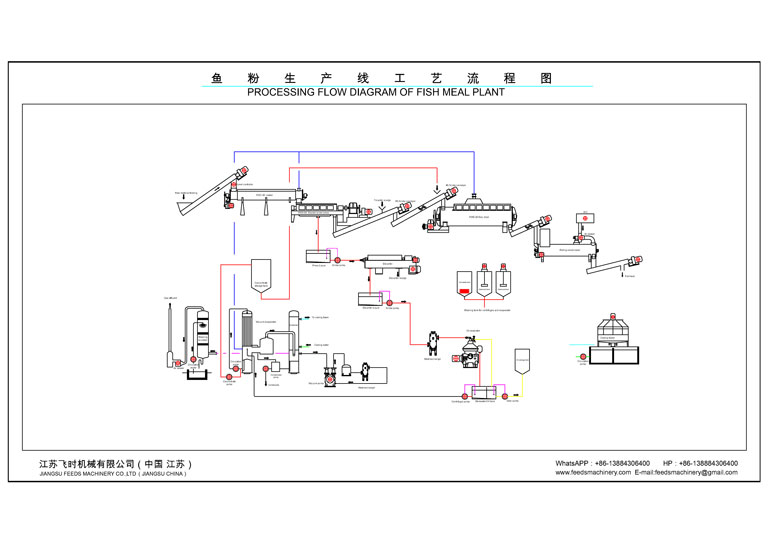

Fish meal production involves various types of machinery, including cookers, pressing machines, dryers, grinders, and coolers. While each machine plays a unique role in the production process, investing in a complete production line with all necessary equipment will influence the overall cost. A full-scale fish meal production line typically costs more but is designed for efficiency and high output. - Level of Automation

Automation is another crucial factor affecting fish meal plant machinery cost. Automated systems allow for better control, reduce labor costs, and improve efficiency. However, these systems come at a higher initial investment. For businesses looking to optimize labor and increase productivity, fully automated machines are an excellent choice, though they will increase the overall machinery cost. - Material Quality and Durability

High-quality fish meal machinery is built to withstand harsh conditions, including exposure to saltwater and high temperatures. Machines made from durable materials such as stainless steel have a higher upfront cost but offer long-term durability, reducing maintenance and replacement expenses over time. - Additional Features and Customization

Additional features such as energy-efficient motors, advanced control panels, and emission reduction technology can add to the cost of fish meal machinery. However, these features enhance operational efficiency and environmental compliance, making them worthwhile for many businesses.

Average Cost Ranges for Fish Meal Plant Machinery

While actual costs vary based on the factors mentioned above, here are some average price ranges for fish meal plant machinery:

- Small-Scale Fish Meal Machines: $10,000 – $100,000. These machines are suitable for small to medium-sized operations.

- Medium-Scale Fish Meal Production Lines: $100,000 – $300,000. These setups provide higher capacity and are well-suited for growing businesses.

- Large-Scale Industrial Fish Meal Plants: $300,000 and up. These lines offer the highest capacity, full automation, and advanced features.

Why Choose Our Company for Fish Meal Plant Machinery?

Our company is a trusted name in the fish meal machinery industry, known for providing reliable, high-performance fish meal plant solutions. Here’s why we stand out:

- Customized Solutions to Fit Your Needs

We offer a range of customizable fish meal machinery, allowing us to tailor our equipment to fit your specific production requirements. Whether you need a compact machine for a small operation or a high-capacity production line for large-scale manufacturing, we have solutions that align with your goals. - High-Quality, Durable Equipment

Our fish meal machines are built using high-grade materials, ensuring durability and longevity. Our commitment to quality means you receive machinery that can handle the demands of daily production while minimizing maintenance needs. - Energy-Efficient Designs

Operating costs are a significant consideration in fish meal production. Our fish meal plant machinery features energy-efficient designs, reducing power consumption and lowering operational expenses. By optimizing energy use, our machines not only save costs but also support sustainability. - Comprehensive After-Sales Support

We believe in building lasting relationships with our clients. From installation and training to maintenance and support, our team is here to ensure your fish meal plant runs smoothly. Our dedicated customer support team is available to answer questions, resolve issues, and provide assistance whenever you need it. - Competitive Pricing Without Compromising Quality

We understand that price is an important factor for any business, and we are committed to offering competitive prices. Our fish meal plant machinery is priced to provide value without sacrificing quality, ensuring you get a high return on investment.

Making the Right Investment for Your Fish Meal Plant

Choosing the right fish meal plant machinery is a key decision that will impact your production efficiency, costs, and product quality. By understanding the factors that affect machinery costs, you can make an informed decision. Investing in high-quality, durable machinery may have a higher initial cost, but the long-term benefits in terms of efficiency, lower maintenance, and increased productivity make it a smart choice.

If you’re ready to equip your fish meal plant with reliable, efficient machinery, contact us today. Our team will help you choose the best equipment for your needs, ensuring a seamless setup for your fish meal production line. Let us help you achieve success in the fish meal industry with our expertly designed machinery solutions.